BIM or Digital Twin? Why Everyone in AEC Needs to Know the Difference

Do you ever find yourself confused between BIM (Building Information Modeling) and Digital Twins (DTs)? You’re not alone. At first glance, both concepts seem to be different ways of referring to models. However, upon closer inspection, you'll discover that they serve very different purposes throughout the project lifecycle.

These terms are often used interchangeably in the AEC (Architecture, Engineering, and Construction) industry, and in some respects, that's understandable—BIM is frequently the starting point for Digital Twins. Nevertheless, they are not the same thing. Let's break it down.

BIM: The Foundation Layer

Building Information Modeling (BIM)

Think of BIM as the foundation of digital delivery. It’s a 3D model loaded with design intelligence, including dimensions, materials, facade systems, and specifications. Depending on the authoring process and the Level of Detail (LOD), it can hold everything from basic geometry to fabrication-ready information. What makes BIM powerful is its ability to coordinate geometry, structures, and systems across disciplines—catching conflicts before they hit the field and giving everyone a shared source of truth (Deng et al., 2021).

In practice, BIM creates value across every phase:

Design phase: In the early design phase, BIM enables stakeholders to visualize the project in terms of geometry and aesthetics. It also helps visually analyze constructability and feasibility issues. A BIM model can be used for clearer cost inference and value analysis. Towards the end of the design phase, BIM is useful for clash detection by analyzing how the federated model elements interact with each other. Clash detection helps in fewer redesigns and fewer change orders.

Construction Phase: With Building Information Modeling (BIM), schedules can be linked to the model (known as 4D BIM), which enhances sequencing and logistics. Prefabrication becomes more efficient, as assemblies can be validated digitally before fabrication. During the construction phase, BIM is also utilized to verify how the structural components are assembled on-site. For example, the location of pipes can be checked against the BIM model. Additionally, BIM can be employed to monitor phased construction by using a color-coded model to represent different phases.

Operations & maintenance: At handoff, BIM becomes a digital as-built record. Facilities teams can click into the model to find asset tags, warranty information, and maintenance schedules, making renovations and tenant improvements less painful.

However, I want to emphasize that these use cases are based on ideal scenarios, where the architect, general contractor, and clients are all inclined to use advanced BIM-assisted tools. The bottom line, though, is that BIM by itself is static; while the information is present, it is also static.

What are Digital Twins?

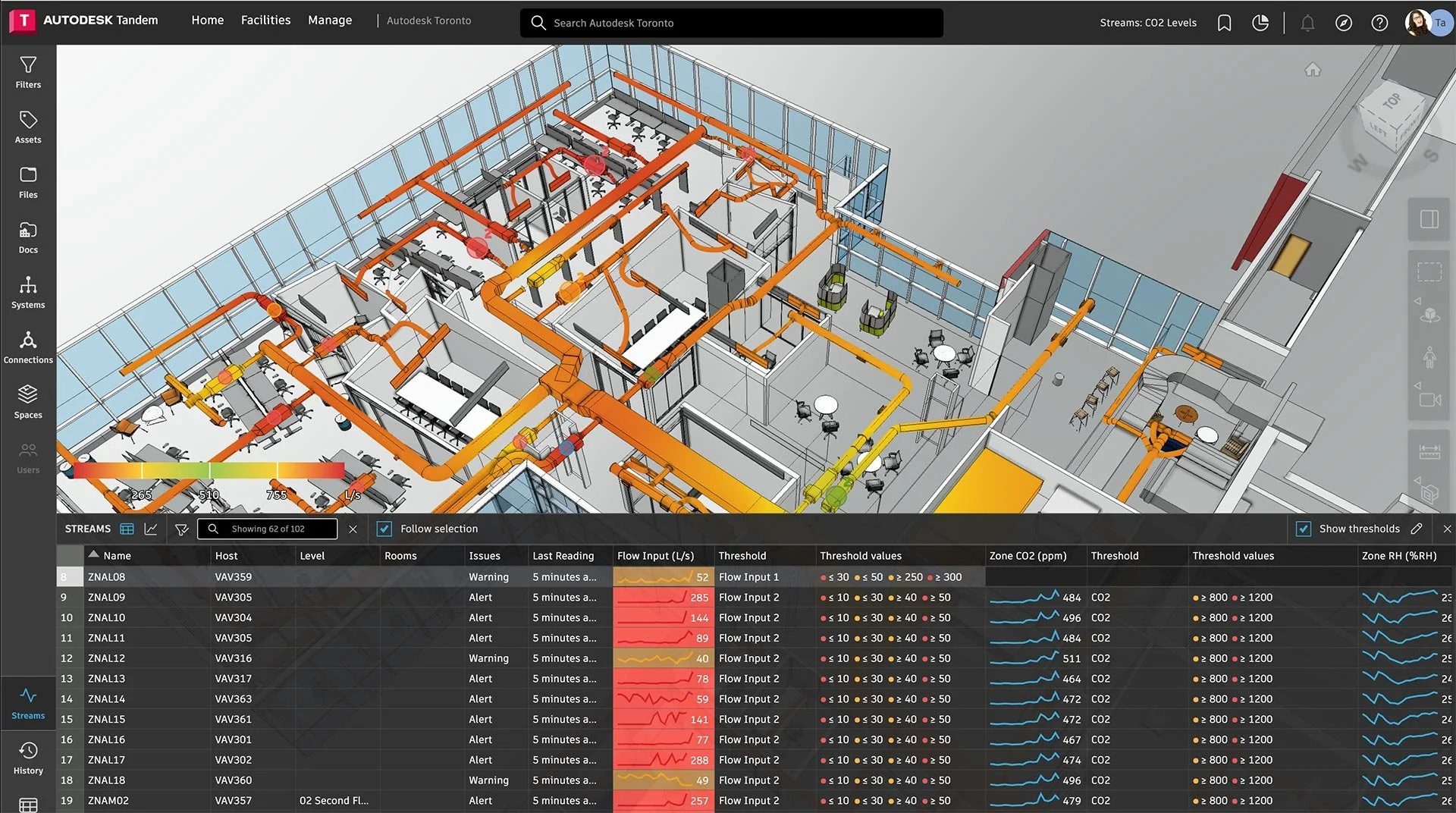

A Digital Twin, on the other hand, is a living, dynamic replica of the physical asset. It doesn’t just show you the geometry of the building; it shows you how the components within it are functioning.

The key difference is the closed-loop of continuous data: acquisition, modeling, O&M management, and data updating. Where BIM is largely static, a Digital Twin evolves through bi-directional feedback between the physical and digital worlds (AlBalkhy et al., 2024).

Across the lifecycle, DTs expand what’s possible:

Design Phase: During the design phase, Digital Twins enable the simulation of “what-if” scenarios. They can be utilized to test energy performance or to model how a new tower impacts the surrounding microclimate. This process involves integrating extensive environmental data, which is often collected through point clouds or Geographic Information Systems (GIS).

Construction phase: DTs provide real-time feedback loops. Monitoring geotechnical data, logistics, and safety metrics allows contractors to adjust plans dynamically. Tunnel boring projects, for example, now use DTs to optimize excavation parameters on the fly (Babanagar et al., 2025).

Operations & maintenance: This is where the true ROI emerges. Predictive maintenance extends equipment life by 20–30%, while energy optimization cuts consumption by 15–25% (Hallaji et al., 2021). At the portfolio scale, owners can benchmark performance across assets, supporting ESG targets and resilience planning.

So if BIM is the still photo, Digital Twins are the live video feed.

Where AEC Stops and FM Begins

Here’s the industry reality: AEC firms generally stop at BIM. Their job is to deliver a safe, documented building. At project closeout, that typically means:

A BIM model enriched with geometry, specs, and asset data.

A set of as-builts and O&M manuals.

Sometimes linked databases for warranties and equipment.

At that point, the baton passes. Facilities managers take over with the tools to operate the building. A Digital Twin lives in their world: integrating IoT sensors, building automation systems (BAS), and CMMS platforms to create a feedback system for cost savings, risk reduction, and long-term performance (Opoku et al., 2021).

The messy part? Handoffs often fail. Owners receive a BIM model but lack the training, standards, or budget to connect it into a live DT. That’s why organizations like ISO (with ISO 19650) and frameworks like COBie are so important—they standardize data so that BIM can evolve into DT instead of sitting idle on a hard drive (Albalkhy et al., 2024).

Are Construction Companies Using DT Today?

Adoption is still limited, but pioneers are testing it:

Bouygues Construction has piloted DTs for bridge monitoring and O&M integration (Albalkhy et al., 2024).

Skanska uses sensor-enabled DTs to monitor concrete curing and site logistics.

CSCEC (China State Construction) is applying DTs at the urban scale, from metro stations to smart city districts.

Airports like Heathrow and Changi have embraced DTs for crowd flow, predictive maintenance, and resilience planning.

General contractors are still primarily BIM-focused. But many are beginning to market DT-ready delivery as a differentiator, partnering with platforms like Autodesk Tandem, Bentley iTwin, and Dassault’s Virtual Twin.

Why This Matters for Owners

For owners and developers, the distinction is simple but powerful. BIM reduces risk before and during construction—giving you confidence that projects will be delivered as planned. Digital Twins unlock value after ribbon-cutting—lowering O&M costs, boosting sustainability, and increasing tenant satisfaction.

Think of it this way:

BIM helps you get it right the first time.

Digital Twins help you keep it right over time.

For any owner looking to maximize asset value in an era of tight capital, high ESG demands, and operational risk, understanding the handoff between BIM and DT isn’t optional. It’s the baseline for how tomorrow’s assets will be designed, delivered, and sustained.

References